Pertechs has its own, in-house developed, software for Lap Time Simulation. Pertechs LapSim is a state-of-the-art simulation tool that use a vehicle model including more than 500 parameters. It has been developed and tested at various racing teams and categories for nearly two decades and has contributed to performance gains and knowledge that otherwise would have been impossible. The software is build around a unique foward calculation technique giving a lot of benefits, for example, it enables calculation of tire and brake temperatures, tire degradation and damper behaviour. This makes the quasi-static model to be much more than just that.

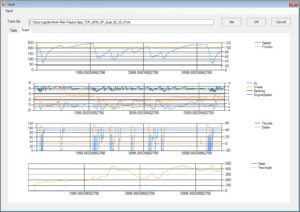

The software has functionality to do single lap runs or multi lap runs meaning that trends over complete race runs can be evaluated. It also has a number of special simulation features, for example "Track Replay" which is a simulation technique where the speed profile around the circuit is kept constant to enable evaluation of parameters without including the influence of varying speed which in some cases can be very helpful, for example when looking at aerodynamic behaviour vs different ride heights.

What's in it for you?

To give a few examples of what can be evaluated with Pertechs LapSim software:

Pertechs can support teams with lap time simulations to for example:

Track Model

The track model defines the racing line around the circuit that the vehicle will follow. To build this path the minimum number of channels required are Distance, Vehicle Speed and Lateral Acceleration, if data is available for the track. If no data is available, perhaps because the track has never been visited before, Pertechs has a well proven method for creating what is necessary anyway by building the path from information from for example Google Earth. By this method, a lot of useful data can be simulated and created before an event on a, for a racing team, unknown circuit.

It is then possible to improve the accuracy of the track model by adding information about local banking, grade and grip levels. In addition to this the track model consist of over 30 more parameters that can be varied locally around the lap to simulate for example local weather conditions (wind or temperature), engine characteristics, aero performance (DRS or slip stream), driver behavior etc.

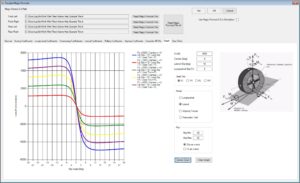

Tire Model

The Tire model can be run as a basic version or highly advanced running for example Pacejka 5.2 with the addition of a thermal model and a wear model.

The thermal model makes it possible to simulate tire temperatures and their effects on grip levels at every calculation point around the lap and also from lap to lap during a longer stint, as a race distance.

The wear model makes it possible to predict lap time degradation during race runs depending on circuit parameters, ambient conditions and setup variables as well as driving styles.

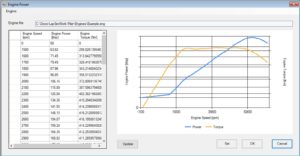

Engine and Drive Train Model

The engine model consists of a text file representing the engine power vs engine speed. In addition to that a number of parameters can be specified for gear ratios, gear change rpm's, differential settings, fuel consumption etc. Rear wheel drive, front wheel drive or all wheel drive can all be modelled.

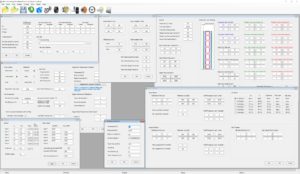

Vehicle Model

The vehicle model consists of a text file that includes all the necessary parameters to decribe the vehicle in terms of dimensions, weights, ride springs, antiroll bars, suspension geometries, aerodynamics, brakes, steering etc. The model is a fully assymetric four wheels model with longitudinal and lateral load transfer included.

DOE Tool

Pertechs Lap Time Simulation has a built in DOE tool that enables multi-runs to be performed meaning thousands of designs can be tested automatically. This can be used for example as a preparation for a race weekend to see trends in vehicle performance and behaviour depending on parameter combinations. There are a number of ways that the DOE can be set up. One or several parameters can be swept against each other to see the sensitivity for each of them and correlation between them. Also complete track files, setup files and engine files can be added to the DOE meaning that for example, a number of engine dyno runs can be evaluated on all circuits for the season with different combinations of gear ratios. DOE plans and result data can be both imported from and exported to MS Excel meaning that the batch run can be organised in MS Excel beforehand and the result can be post processed in MS Excel afterwards if convenient.

Result File

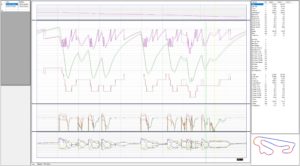

The output file consists of around 250 channels that can be viewed directly in Pi Toolbox or Motec i2 or exported as csv to be imported in any preferred analysis software. There is also an integrated analysis tool in Pertechs LTS where all the data can be interpreted.

Please contact us if anything above is of interest and we can discuss a solution that fits your requirements.